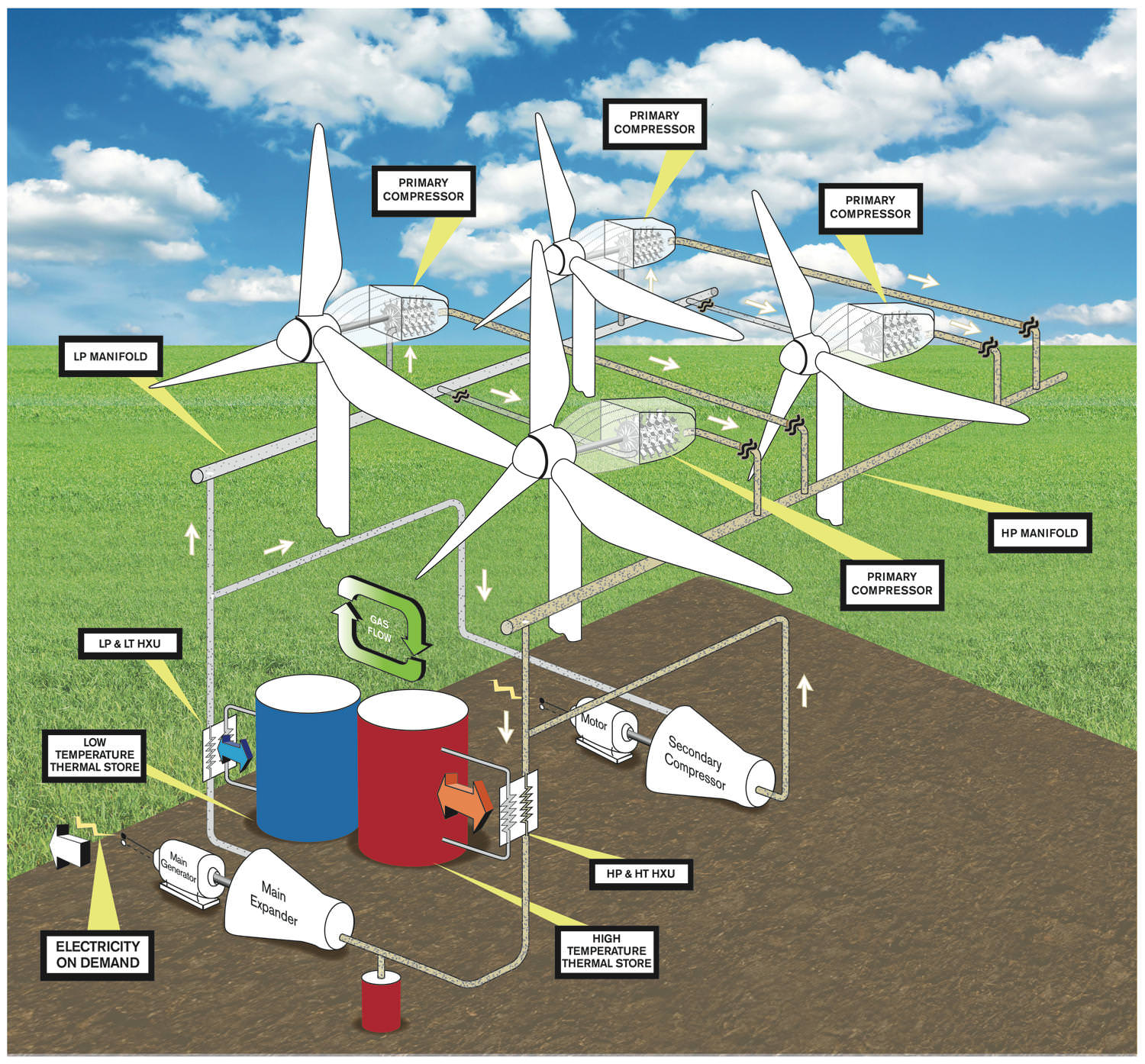

System overview

The illustration shows a schematic of what WindTP comprises. Power is transmitted from the wind turbine rotor to the electrical generator through movement of gas within a closed gas circuit. The low pressure (LP) side of the circuit is at ~20bar (20 times atmospheric pressure) and the high pressure (HP) side of the circuit is at ~500bar (500 times atmospheric pressure). These pressures always remain the same - even when the system is not running.

Power is put into the gas circuit by special primary compressors driven directly by wind turbine rotors. The primary compressors draw gas from the LP side and eject it into the HP side. Because the compressors are deliberately designed to be very efficient and to minimise heat transfer and because the pressure ratio (HP:LP) is 25:1, the (absolute) temperature of the gas emerging from the primary compressor is around 2.5 times greater than the (absolute) temperature of the gas

Power is removed from the gas circuit by an equally-special expander which uses its output work to drive a generator. The expander is also deliberately designed to be very efficient and to minimise heat transfer. Gas enters the expander approximately 2.5 times hotter than it leaves.

A heat exchanger fitted on the HP side of the closed gas circuit enables the system to sustain a temperature difference between the primary compressor outlets and the expander input. Similarly, a heat exchanger fitted on the LP side of the closed gas circuit enables the system to sustain a temperature difference between the primary compressor inlets and the expander output.

A hot store enables heat to be removed / re-injected into the 500bar gas on the HP side of the closed gas circuit. A cold store enables coolth (coldness) to be removed / re-injected into the 20bar gas on the LP side of the closed gas circuit. The storage of heat and coolth equips the system to deliver dispatchable power.